Performance Products use World-Class LEDs

Our long-term partnerships with the world's leading LED manufacturers mean we only use LEDs of the highest quality and performance.

High Quality starts with Engineered Products

With a passion for quality and perfection, we engineer our products in-house to the last detail, including our LED printed circuit boards (PCBs), electronic drivers, software, mechanical housings, and optics.

Starting with great LEDs is important, however how LEDs are managed in a system makes all the difference.

Customization

Being both the designer and manufacturer of our products means flexibility for our customers.

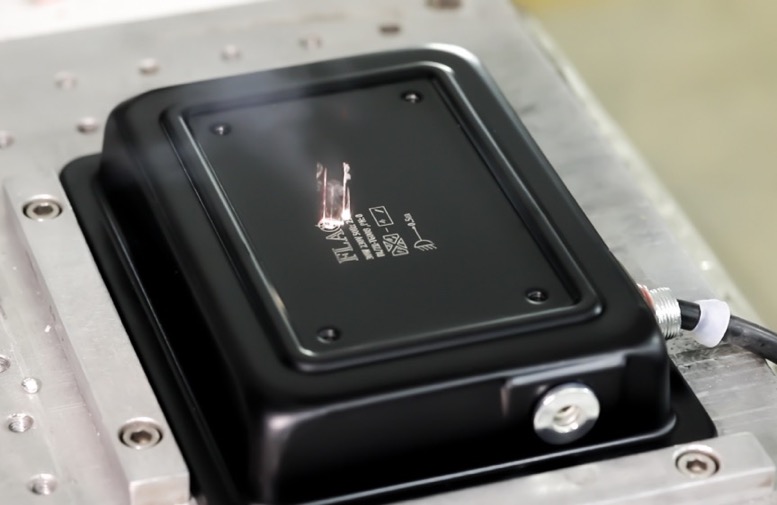

Manufacturing LED FloodLight

Engines In-House Has Its Benefits

Highest Quality

Made-in-the-China quality with fully automated inspection systems.

Flexibility

We offer more color temperatures, LED colors, and customizable features than other LED fixture manufacturer.

Speed

In-house manufacturing means quick turnaround, even for special configurations.

Availability

By not relying on 3rd party LED boards, we aren't subject to color mismatch or surprise obsolescence.

customizable features than other LED fixture manufacturer.

LED Fixture Assembly

Electrical Panel Assembly

Metal Fabrication

Wire & Cable Processing

In-Process Inspection

Leak Testing

We employ a 100% leak test inspection system for our outdoor linear products. Each floodlights is connected to a highly sensitive measurement system that pressurizes the fixture with a gaseous mix and allows our inspectors to verify proper sealing.

Burn-In

Select RRR products are 100% burned-in prior to shipment. The burn-in process assists in verifying proper functionality at-temperature and over time (typically 24 hours).

Long-Term Testing

Throughout the life of a product line, we operate a representative sampling of led floodlight at elevated temperatures and observe lumen maintenance and performance over time.

Shipping

We ship our led floodlights worldwide, directly from our factory or through our distribution network.

OEM & Kitting

For OEM customers, we offer additional logistical support through product kitting.

Logistical Support

Further logistical support includes specialized inventory management programs, build-to-forecast, and shipments to multiple locations.